Introduction:

MS Channel or The Indian Standard Medium Channel (ISMC) is a crucial weight chart used in the Indian steel industry for calculating the weight of various steel products. This chart takes into account the dimensions of steel products, including width, height, and length, to determine their weight. It serves as a vital tool for manufacturers to establish the pricing of their products accurately. Additionally, customers utilize the ISMC weight chart to compare prices of different steel products effectively. By providing precise weight measurements, this chart aids in ensuring fair pricing and transparency within the steel market, benefiting both manufacturers and consumers alike.

What is an MS Channel Weight Chart?

An MS channel, also known as a C-channel or U-channel due to its cross-sectional shape, is a type of structural steel used primarily in construction. These channels are manufactured from mild steel, a material known for its excellent weldability, ductility, and toughness. MS channels come in various sizes, each with different dimensions and weight specifications, making them suitable for multiple applications, from building frameworks to machinery and vehicle structures.

Importance of MS Channel Weight Chart

The weight of an MS channel is a critical factor in its design and application. The weight affects the structure’s searing capacity, stability, and safety. Here are some key reasons why the MS channel weight chart is essential:

- Load Calculation: Accurate weight measurements are essential for calculating the channel’s load-channel capacity, ensuring it can support the intended load without failure.

- Cost Estimation: Understanding the weight of MS channels is essential for accurately estimating material costs, transportation expenses, and overall project budgeting.

- Structural Integrity: Ensuring proper weight distribution is critical for maintaining the structural integrity and balance of constructions, especially in large-scale projects.

- Compliance and Standards: Adhering to industry standards and regulations necessitates precise knowledge of material weights, as specified in ‘weight materials’.

Understanding the MS Channel Weight Chart

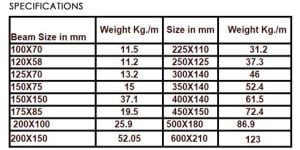

An MS channel weight chart typically lists various sizes of channels along with their corresponding weights per unit length (usually per meter).

This chart indicates the channel size by height, width, and thickness (in millimetres); the corresponding weight is in kilograms per meter.

Factors Affecting MS Channel Weight

The weight of an MS channel depends on several factors:

- Dimensions: The channel’s height and thickness directly impact its weight. Larger dimensions result in heavier channels.

- Material Density: Mild steel has a specific density (approximately 7.85 g/cm³), which calculates the channel’s weight and volume.

- Manufacturing Process: The method used to manufacture the channel, such as hot rolling or cold forming, can slightly affect its weight due to final dimensions and density variations.

Applications of MS Channels

MS channels are widely used across various industries due to their versatility and strength. Some typical applications include:

- Construction: MS channels are used in building frameworks, supporting beams, and structural reinforcements in residential, commercial, and industrial construction projects.

- Machinery and Equipment: Due to their robust nature, they are utilized in the manufacture of heavy machinery, agricultural equipment, and industrial machinery.

- Transportation: MS channels are used to construct vehicle frames, chassis, and other structural components in the automotive and railway industries.

- Infrastructure Projects: MS channels are essential in infrastructure projects like bridges, highways, and tunnels, providing critical support and stability.

- Storage Systems: Because they can bear significant loads, they are used to create storage racks, shelves, and other storage systems.

How to Calculate MS Channel Weight

Calculating the weight of an MS channel involves using the channel’s time channel and the density of mild steel. Here’s a step-by-step guide:

- Determine the Volume: Calculate the cross-sectional area of the channel and then multiply by the length to get the volume.

- Use the Density: Multiply the volume by the density of mild steel (7.85 g/cm³ or 0.00785 kg/cm³).

Example Calculation

For a channel with dimensions 100 mm x 50 mm x 6 mm and a length of 1 meter:

- Cross-Sectional Area: Calculate the area of the web and the flanges:

- Web: 100 mm x 6 mm = 600 mm²

- Flanges: 2 x (50 mm x 6 mm) = 600 mm²

- Total Area: 600 mm² + 600 mm² = 1200 mm²

- Volume: Area x Length = 1200 mm² x 1000 mm = 1,200,000 mm³ = 1200 cm³

- Weight: Volume x Density = 1200 cm³ x 0.00785 kg/cm³ = 9.42 kg

Thus, the weight of the channel is approximately 9.42 kg per meter.

Selecting the Right MS Channel

Choosing the appropriate MS channel involves considering several factors:

- Load Requirements: Understand the load requirements of your project to select a channel with sufficient load-bearing capacity.

- Environmental Conditions: Consider the environmental conditions, such as exposure to moisture, chemicals, or extreme temperatures, and choose a channel with suitable protective coatings if necessary.

- Compliance with Standards: Ensure that the selected channel meets industry standards and regulations for safety and performance.

- Cost and Availability: Evaluate the price and availability of different sizes and weights to find the most cost-effective solution for your project.

Maintenance and Handling of MS Channels

Proper maintenance and handling of MS channels are essential to ensure their longevity and performance:

- Storage: Store MS channels in a dry, clean environment to prevent corrosion. If necessary, use protective coatings.

- Handling: Use appropriate lifting equipment and techniques to handle heavy MS channels safely.

- Inspection: Regularly inspect MS channels for signs of wear, corrosion, or damage and address any issues promptly.

Conclusion:

The MS Channel Weight Chart is vital for engineers, builders, and manufacturers. It provides essential information for selecting the proper channels for various applications. Understanding the weight, dimensions, and applications of MS Channels helps ensure the structural integrity, safety, and cost-effectiveness of construction projects and other industrial applications. Using the MS channel weight chart and following the best selection, maintenance, and handling practices can help you achieve optimal project performance and durability.